Cartridge Filters Maintenance Tips

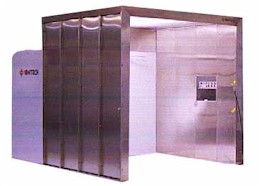

A powder booth is an enclosure that is designed to contain the powder application process.

A recovery system is attached to the powder booth shell. The recovery system uses a fan to pull air into the booth and prevent the oversprayed powder from migrating out of the enclosure.

The simplest powder booths are designed for a single operator to

manually apply powder to a stationary product. Other booths are designed so that parts can be conveyed through the enclosure.

Conveyorized systems may be designed for manual application from

two sides, automatic application, or a combination of both, depending on the system requirements. The particular style, size and number of powder booths needed is related to the product size, the available space, the amount of capital and the volume of product to be coated.

Powder booth shells are occasionally made of painted steel but more

often they are made of stainless steel, polypropylene, polycarbonate

or other clear plastic, and a few are made of glass or polyethylene

sheet.

Painted steel is adequate but there is some risk that the paint

will chip off and contaminate the oversprayed powder in the reclaim

system.

Stainless steel makes a very durable booth shell with a smooth

surface for ease of cleaning.

Plastic walled booths offer an easy to clean surface and the walls can allow some light to penetrate into the spray area and help illuminate the process. A nonconductive plastic walled booth will collect less charged powder on the walls. This means

that they can be easier to clean. It also means that they do not attract as much powder that might otherwise be attracted to the part, so they provide a modest improvement in transfer efficiency.

The part size will influence the height and width of the booth and the

required product opening. The opening size must allow the part to

enter with proper clearance around the edges. In most cases, the

clearance is 6" between the largest part and the edges of the opening.

In a conveyorized system, the booth shell should extend at least 18"

above the opening to keep the hook site well above the spray zone.

The amount of opening in the booth will determine powder containment air requirements.

In order to contain the oversprayed powder, the collector fan is designed to provide 100-120 lineal feet per minute (lfpm) of air velocity across all openings. Properly designed, the booth

will have even airflow throughout the enclosure and not interfere with

the coating process. Collector fan sizing must also consider safety.

Each powder is rated with a lower explosion level (LEL) measured in

oz/ft 3 . The booth must be designed with enough ventilation to keep

the powder concentration level below 50% of the LEL. The number

of guns and nominal powder output per gun determines concentration.